Optimal goods location with ABC analysis

LOGIA WMS expert advice

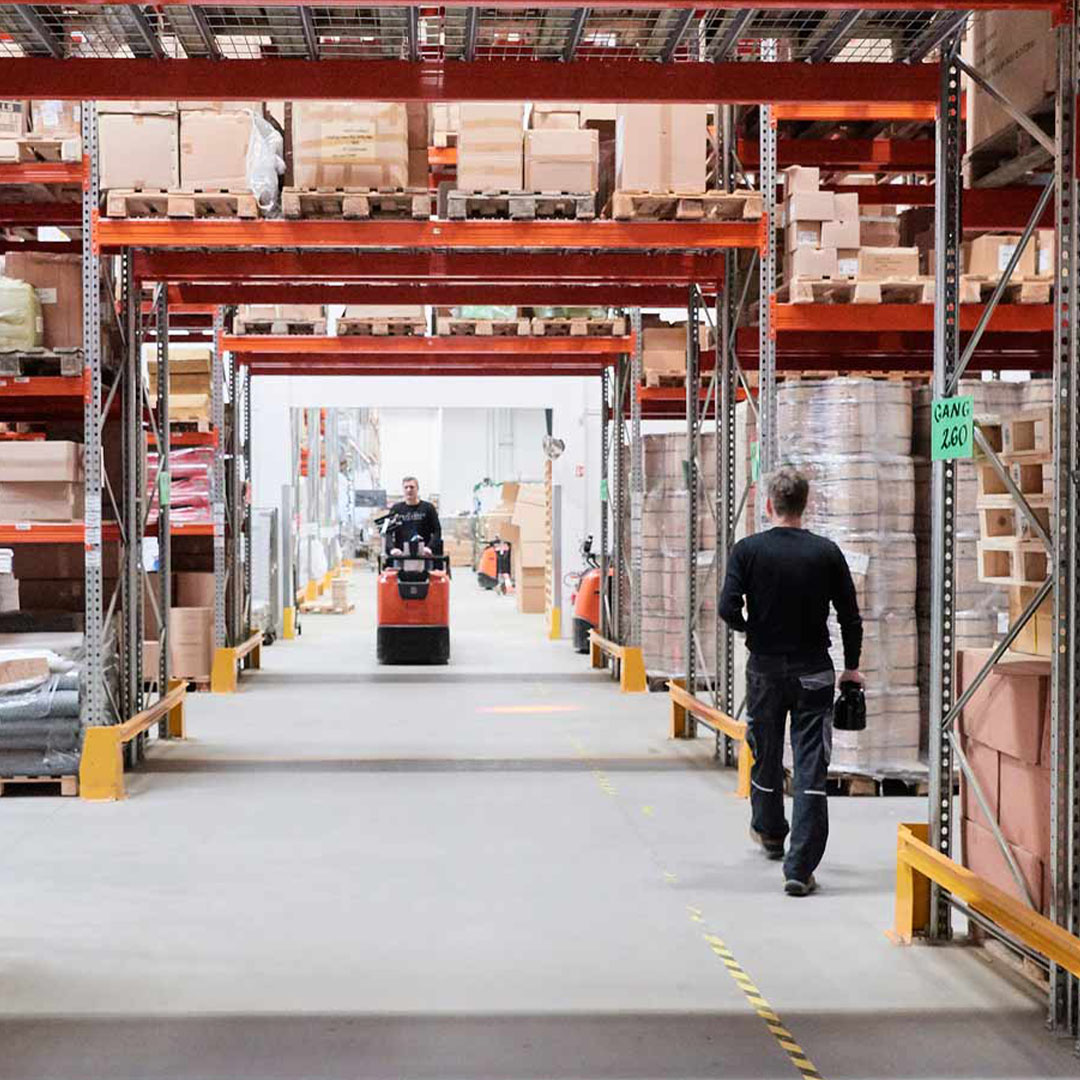

What is an ABC warehouse?

An ABC warehouse means that the warehouse goods locations are based on an ABC analysis that provides insight into the optimal location of the goods. To achieve the most efficient warehouse processes, we recommend that you carry out an ABC analysis.

An ABC analysis can be used as a management tool for efficient warehouse management. The purpose of optimizing the location of the goods is to streamline the workflows for storing and picking.

ABC analysis in the warehouse

The optimal location of goods is generally determined by the picking frequency. Goods with high picking frequency are placed at A locations, goods with medium picking frequency are placed at B locations, and goods with low picking frequency are placed in C locations. The locations are categorized in the warehouse according to picking, storing, and ergonomic height.

The ABC categorization of the goods may change over time – for example, a C item can become an A-item. The analysis can be used for continuous improvement and simple relocation of items based on the ABC classification. You get an overview of which items are inappropriately located and insight into the best location of the goods.

Warehouse management with ABC analysis

In the LOGIA warehouse management system, it is easy to perform an ABC analysis based on the picking history of an item and its location in the warehouse. LOGIA visualizes which items are inappropriately located and suggests new locations for the items. LOGIA guides the employee through the relocation of the items.

Contact us to learn more about the ABC analysis in LOGIA.

A “C” item can become an “A” item

The optimal goods location is challenged over time by changes in marketing patterns, product ranges, and so on, which means that the products that are C goods today can be A items tomorrow.

LOGIA’s warehouse management gives you an overview of which goods are poorly placed — either within a single warehouse area or across the entire warehouse. This allows for the start of moving jobs when and where appropriate.

Internal transportation is minimized

LOGIA warehouse management ensures that goods are stored at the optimal locations and that inventory is replenished at the picking sites. The platform provides an overview of whether any goods are poorly placed. This creates a good warehouse flow and efficient picking rounds.

It is nothing new that A items should be placed in A-locations, which are the most readily available and which require minimal internal warehouse transportation, that B items should be placed at B-locations, and so on.

In LOGIA, the master data of the goods can be supplemented with storage and replenishment strategies. This means that LOGIA can assign the best possible location for the individual item in storage. This may be directly on the correct picking location, or (if there is inventory in the picking location) at a free buffer location close to the picking location.

In addition, LOGIA initiates replenishment jobs when inventory drops below the specified minimum. This ensures that intercompany transportation is minimized and that no picking is started on orders that contain goods that have no inventory on the picking places.

Insights

-

Supervin's warehouse management

Supervin's warehouse management yields impressive results

Content type: News -

Besko boosts efficiency

Besko boosts efficiency by 78% with vertical storage lifts and WMS

Content type: News

Want to know more about LOGIA WMS?

Explore further by scheduling a demo through the form or by reaching out to one of our experts directly. We're here to assist you!